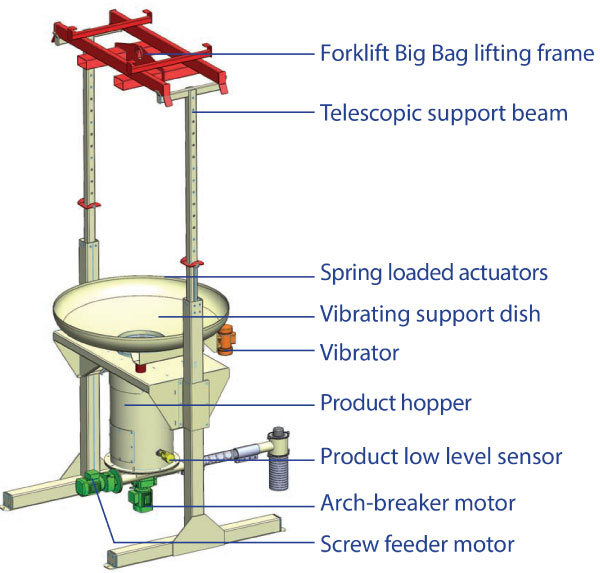

Sodimate’s big bag discharger units are designed to store 35ft³ and 70ft³ capacity big bags, FIBC bags, bulk bags, or super sacs. The big bag can be placed on the frame using standard handling methods, such as a forklift or overhead crane, or the unit can integrate its own manual or electrical hoist.

Common dry chemicals stored in the big bag discharger include powdered activated carbon (PAC), hydrated lime, polymers, soda ash, clay and sand.

All big bag unloaders come equipped with a Sodimate mechanical arch-breaker/discharger and volumetric screw feeder, which can be flexible or connected to an inclined conveyor to vertically transfer the product to the discharge point.

The big bag discharger is supported by telescopic, spring-loaded arms and loaded on a vibrating dish which vibrates only when the product sensor detects a lack of product in the hopper. This set-up ensures complete emptying of the bag and signals the operator when it is time to replace it.

Easy assembly and disassembly makes the discharger ideal for mobile applications, including tests and trials. Typical applications include sludge treatment, and slurry systems.

The units are suitable for a variety of container designs and capacities. The Big Bag or Fibc Bag or Bulk bag can be placed on the frame with classical handling methods (fork lif, hoist, etc…). Our discharge systems for Big Bag or Fibc Bag or Bulk Bag are designed to meet the requirements of these type of storage. They are employed on installation where is needed dosing system of Activated Carbon, Hydrated Lime, Quick Lime.