The injector screw transfers or injects dry chemicals into a sludge mixer, slurry tank or gas stream while isolating moisture, heat and condensation from the dry chemical. Injector screws are used in place of isolation devices such as pinch valves, slide gates, rotary airlocks, and butterfly valves.

Located between the feeder outlet and the injection point, Sodimate’s injector screw is made of reinforced spring steel with stainless steel 304 casing and is driven by a reinforced geardrive. Various types and sizes are available depending on the desired discharge rate and application. Most injectors are installed with hygroscopic materials such as quicklime (CaO) Magnesium Oxide (MgO), and polymers.

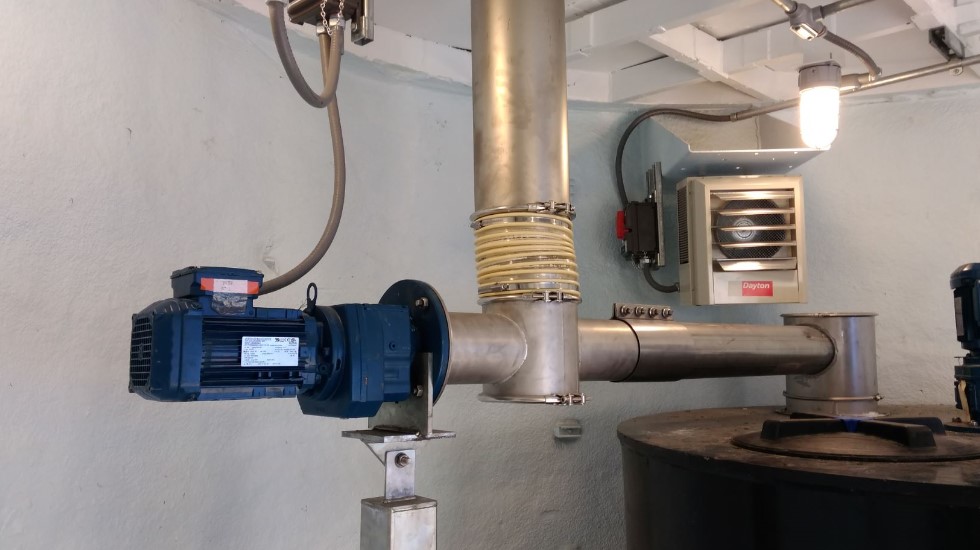

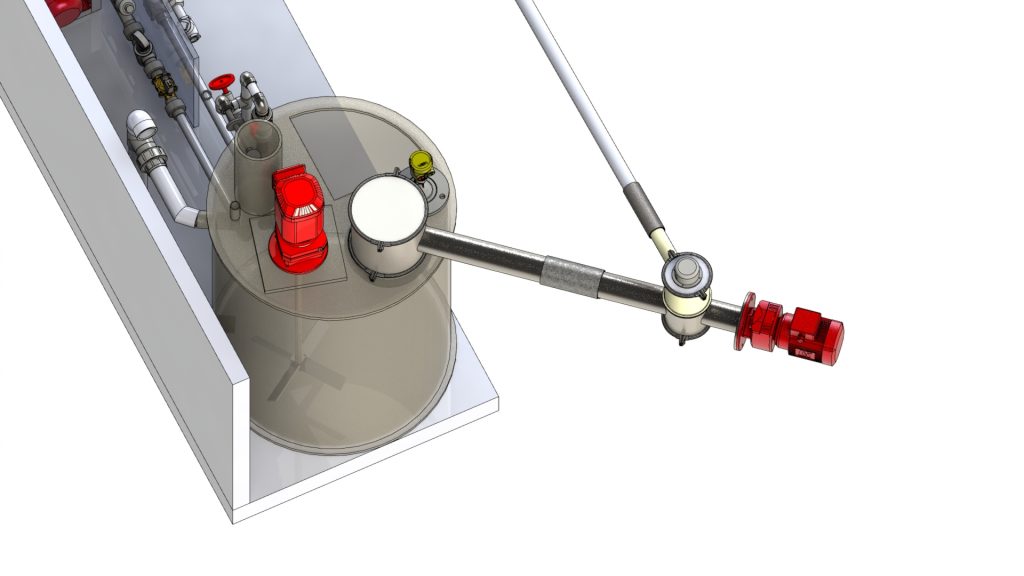

Installation examples

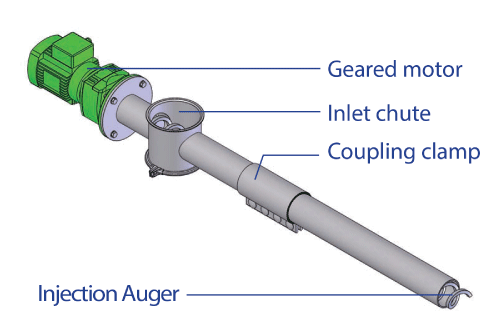

Operation:

The injector screw is composed of an inlet chute, a reinforced screw and a geardrive.

The power of the motor is oversized and the screw is reinforced in order to sustain difficult operationg conditions generated by moisture, steam or pressure mixed with powder in the ambiant atmosphere.

Advantages

- Replace airlocks/slide gates

- Prevents dry chemical blockages

- Protects upstream conveying equipment

- Injectors are made of SS 604 (or 316 per request)

- Minimizes dust emission

- Requires no preventive maintenance

- Easy installation/disassembly

- Cost-effective