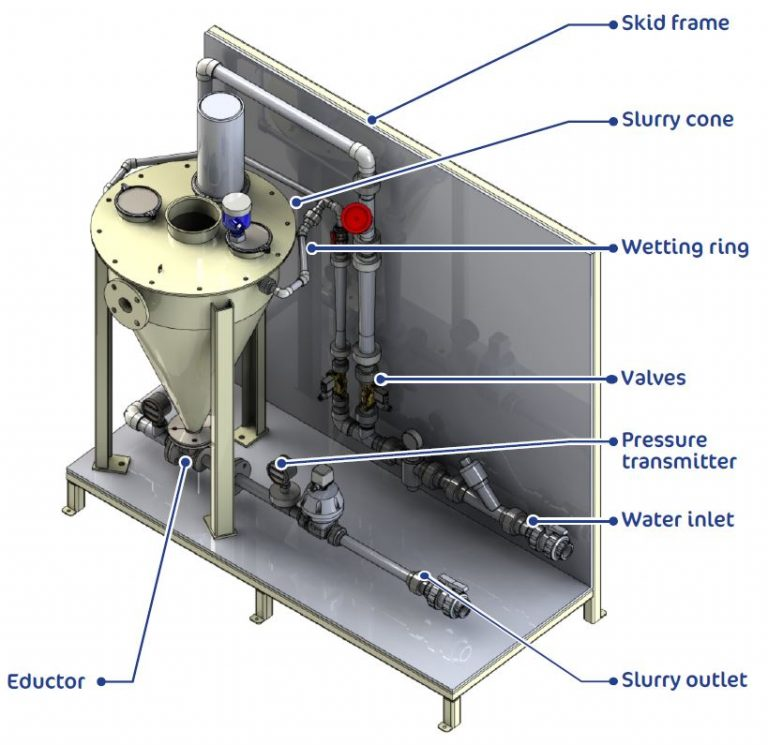

To provide Microsand & Powder Activated Carbon (PAC) mixing installations that facilitate a homogeneous and 100% dustless operation, Sodimate designed, and manufactured, in addition to our regular mixing tanks, its PAC wetting cone with Hydroejector / Eductor Jet Pump.

Sodimate’s Venturi Eductor/Hydroejector eliminates the use of a slurry mixing tank and reduces the electrical consumption and floor footprint. The resulting slurry can be transferred horizontally and vertically with a few pounds of pressure at the process end injection point.

Hydroejector Advantages

Sodimate’s Hydroejector/ Eductor System has a lot of advantages, which are mentioned below:

Advantages :

- Dust free operation

- Long transfer distances with elevations and back pressure

- Low energy consumption

- Can be mounted on a skid

- Optional instrumentation

Hydroejector Operation Principle :

Sodimate Hydroejector or eductor jet pumps use water or other liquids under pressure as the motive fluid and operate on the Venturi principle to mix dry chemicals into slurries.

Water is constantly injected inside the slurry cone to provide instantaneous hydration, reduce dust, and avoid clumps. The high-velocity jet of liquid from the hydroejector/ eductor nozzle creates a vacuum, which causes the suction of the mixed liquid.

Sodimate eductor systems are the ideal way to continuously produce solutions and well blended slurries that are commonly used in chemical, food, power, pharmaceutical, and wastewater applications.

The slurry eductor can be supplied with all necessary flow, pressure, control, and regulation instrumentation.

More information is available about the processes that use Powder Activated Carbon on the EPA website.

Hydroejector Features

- Slurry transfer without mixing tank

- Can be adapted to existing process

- Dust unit free system

Hydroejector Option

- Contact parts made out of stainless steel

- Explosion proof instrumentation

- Skid mounted system