pH control is an important parameter in many processes such as water production, wastewater and industrial wastewater treatment processes. Sodimate’s lime slurry systems provide the pH Control and pH Adjustment through the addition of hydrated lime (calcium hydroxide) or quicklime (calcium oxide) each requiring specific dry-to-slurry equipment.

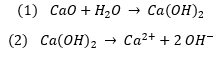

These reagents release hydroxide ions into the water, which increases its pH thanks to these different reactions. The transformation of calcium oxide (CaO) is based on formulas 1 and 2 while the reaction of calcium hydroxide () is described by formula 2.

Lime can also be used as a reagent to purify and balance water. Thanks to the precise regulation of Sodimate’s lime slurry systems, it is possible to remineralize the water when it no longer contains enough ions. Slurry systems can also be used to reduce the hardness of water by precipitating bicarbonates to avoid the formation of limescale when the water has a high mineral content (and ) and a high P alkalinity.

Facilities that use quicklime will require a lime slaker on-site to create a hydrated lime slurry prior to being fed to the stream of water, while facilities that use hydrated lime will only require a slurry mixing tank. The complete lime turnkey system would also include:

- Storage Container for powdered lime, such as a silo, hopper, or super sac

- Gravimetric or volumetric screw feeder

- Isolation injector to protect the screw feeder from moisture and humidity

- Lime slurry tank with skid pumps