Sodimate supplies a complete pneumatic conveying system to inject powder into your process, from the storage to the fumes duct.

Pneumatic Conveyor Application:

Sodimate pneumatic conveying systems can convey powders over long distances, with a flow rate range from 0.5 lb/h to 2,200 lb/h.

Pneumatic conveying systems are the best alternative to screw conveyors when the installation requires complex paths and a high injection point that would otherwise be difficult to reach.

Pneumatic Conveyor Description:

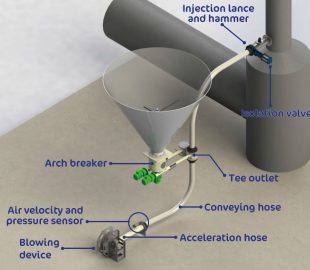

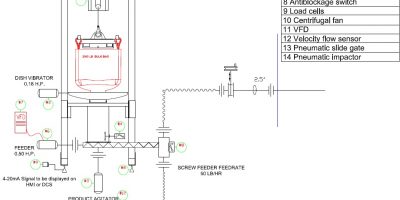

The Sodimate Mechanical Arch Breaker discharges and doses the product stored in the silo or Big Bag emptying stands to a Tee to which the blowing device is connected. Then the compressed air conveys the powder to the injection point through a pipe.

The pneumatic conveying is done in a dilute phase, allowing us to operate with a low pressure and cost-effective blowing device, e.g. a fan or a regenerative blower.

Features of a Powder Conveying System:

The isometry and the negative pressure at the injection point are considered when sizing the systems to comply with the standard air flow rates of each powder.

A Pitot probe located on the acceleration hose measures the air velocity and pressure to regulate the blower speed and the airflow accordingly.

The screw feeder outlet is coated with a anti-stick liner to discharge the powder into the pneumatic conveying pipe.

Sodimate pipes are transparent, flexible, light and easy to install.

Our system includes a custom injection lance specifically designed for each powder and application.

Advantages of a Powder Conveying System:

• Wide selection of hoses

• Operate with low pressure

• Low maintenance

• Possible to transfer over long distances

• Low investment

• Easy installation and start-up

Powders conveyed:

• Powered Activated Carbon (PAC)

• Hydrated Lime with high specific surface area

• Soda Ash

• Clay

• Dry polymer

• Etc.

Pneumatic Conveyor Options Available:

• Non-stick coated steel parts

• Pneumatic hammer on the injection lance

• Up to 4 independent lines under the storage unit

• Regenerative blower