Description :

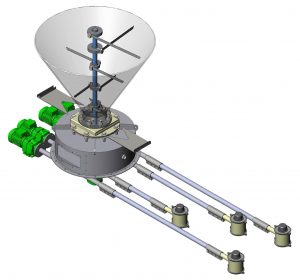

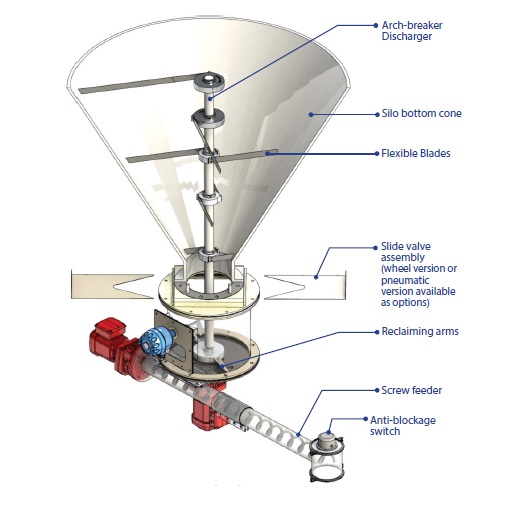

Sodimate’s patented ZDM 400 Mechanical Bin Activator is an innovative and mechanical system that allows the total discharge and an accurate feed of powdered materials stored in silos. The unit can be easily fit onto any silo cone, and is entirely adaptable to a client’s specific needs.

Features of the DDS 400 mechanical bin activator / arch breaker

Cutting-edge technology & industry-leading expertise

Multiple screw feeders: Thanks to our leading expertise and technical know-how, our Bin Activator can accomodate multiple feeders, each feeder functioning independently, capable of sustaining a high flow on one side, and a low flow on the other.

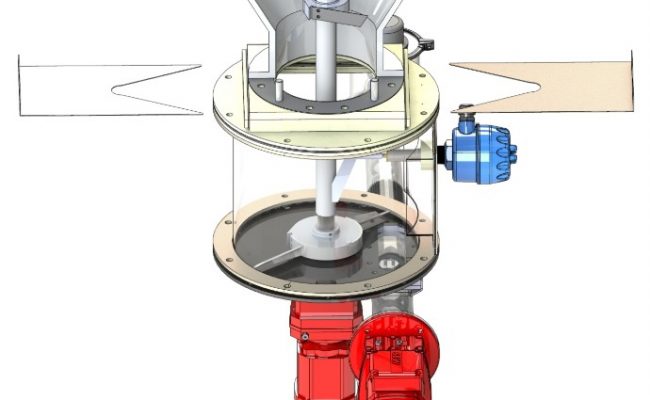

Mechanical extraction of virtually any material, without contamination or variations due to unique ADVANCED DENSITY CONTROL.

Our mechanical bin activator promotes a consistent density discharge of material by using a unique transition hopper. This ADVANCED DENSITY CONTROL of the material facilitates the

volumetric dosing.

Solutions for any type of equipment

• Mechanical Bin activator tailor-made to suit any project

Can be custom built for new projects or adaptable to existing equipment

• Easy and flexible mounting:

360° rotation, adjustable lengths, rigid or flexible augers

Effectiveness & efficiency

• Cost-effective due to minimal maintenance and downtime

• Energy efficient : Low-power geared motors

• Accurate and continuous feed

• Broad range of applications across numerous industries with same high efficiency

• Airless system, allowing no fluidization

• Zero compaction, obstruction or clogging

• Innovative cost-effective 3-in-1 system saving you from purchasing separate equipment

(Bin Activator + Isolation Valve + Screw Feeder)

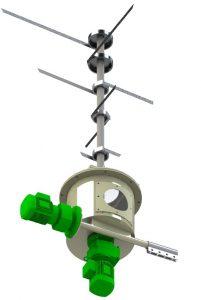

Operation

The main part of the ZDM 400 silo discharger is the mechanical arch breaker. It rotates inside the silo cone thanks to a gearmotor. Its flexible blades prevent the product from arching or bridging in the silo cone, which ensures a constant discharge. The reclaiming arms, which

are also driven by the gearmotor, rotate to completely fill the metering conveyor with product. This ensures an accurate volumetric dosage.

Global technology custom-made in the US

Proven Quality

Over 9000 successful installations worldwide

Managed longevity

Long life-cycle solution with no intrinsic failure mechanisms

Sodimate’s unique silo discharge system uses gentle agitation, rather than vibration or fluidization, when discharging and feeding the dry powder. Vibrators mounted directly on bins or silos can cause issues such as compacting, bridging, and arching. Our silo mechanical bin activator avoids such issues and prevents rat holing and erratic silo discharge often seen with air injection systems & vibration.