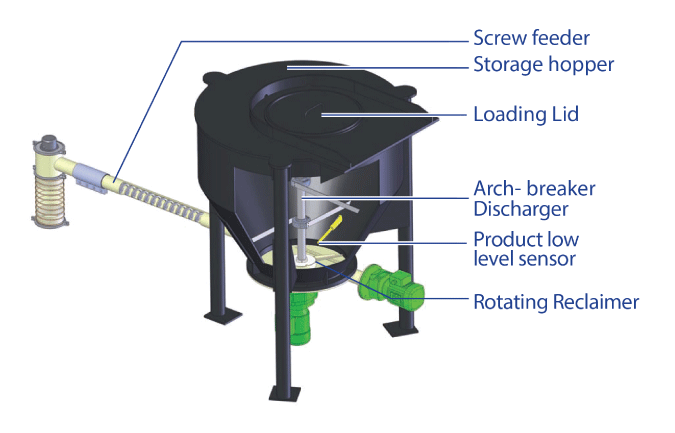

Our screw feeder hopper is ideal for discharging smaller quantities of product delivered in 50 lb bags, such as lime, soda ash, sand, cement, or powdered activated carbon (PAC). These units feature a ZFP 500 mechanical discharge and feed system.

Powder Discharge and Feed System for Storage Hopper

The storage hopper system can be installed under any hopper capacity ranging from 1 to 100 ft3 and offers a compact and ready to use the system.

The Screw Feeder Hopper Design

Sodimate’s screw feeder hoppers are custom-fabricated in sack-tip, buffer, and loss-in-weight models, and can be equipped with one or several volumetric screw feeders (rigid or flexible). The rotating mechanism ensures a total discharge and accurate dosing of the powder. The units can also be furnished with a dust filter, level sensor, mechanical arch breaker, load cells, and a protection grid.

Screw Feeder Hopper Installation Examples

The screw feeder hopper designs include standard and custom sizes

Fabrication material can vary depending on the customer’s needs. Typical fabrication materials include High-density polyethylene (HDPE), painted steel, stainless steel and fiber glass.

Operation:

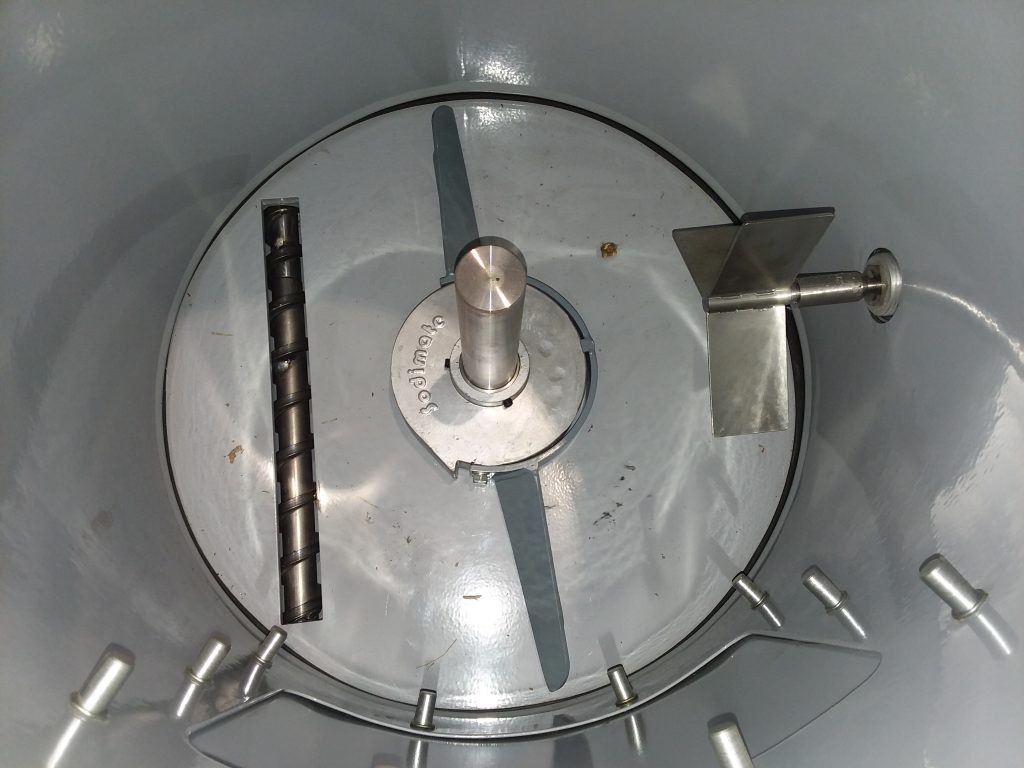

The ZFP 500 is a Sodimate arch-breaking spindle with flexible blades that rotate within the storage hopper’s bottom cone, preventing bridging and blockage. Connected to the arch-breaker spindle is a rotating rigid reclaimer that assists in the discharge and guarantees volumetric accuracy by pushing the powder into the volumetric screw.

Advantages of Sodimate’s Screw Feeder Hopper:

- Low power consumption

- Easy to assembly

- Mechanical discharge without product compaction or contamination

- Adjustable lenght

- Flexible or rigid screw feeder

- Dust-free