Application :

For installations that require high powder metering accuracy, instantaneous flow rate image, or consumption totalization, Sodimate can provide a turnkey Loss in Weight system.

For installations that require high powder metering accuracy, instantaneous flow rate image, or consumption totalization, Sodimate can provide a turnkey Loss in Weight system.

The operation is simple, reliable, with a very high accuracy for industrial applications. This installation allows weight dosing from a buffer hopper placed under or near the silo to the injection point. This mechanism can also be applied to the Big Bag emptying stands.

The mechanical arch breaker and the feeder under the silo quickly fill the hopper up to the highest level.

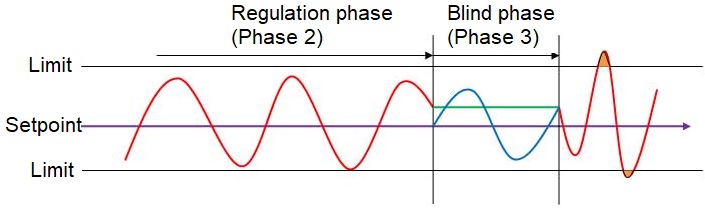

The Loss in weight installation begins and the product is discharged from the hopper. The weighing sensors measure a consistent flow rate that is compared to a setrate saved in the PLC given by an operator or an external signal. If the two rates are inconsistent, the PLC will increase or decrease the feeder’s speed to match until the two rates are exactly the same.

Once the lowest possible level is reached, the loss in weight hopper must be refilled. The installation goes into blind phase, i.e. the electronics are no longer able to measure the input or output. The flowrate then switches to volumetric control according to a taring realized at the start-up. This blind phase must be as short as possible to not reduce the accuracy, that is why the feeding flowrate from the silo is about 10 times higher than the desired flow.

2 types of installation can be designed with weighting equipment: