Sodimate supplies Powdered Activated Carbon (PAC) feed systems to water treatment facilities in order:

- To improve the organoleptic qualities of water by eliminating color (humic substances), taste and smell.

- To reduce non-biodegradable toxic substances (pesticides, herbicides, surfactants, hydrocarbons ….).

- To reduce some cancer-causing compounds such as Tri-Halo-Methane

- To reduce the amount of phosphate in the water and limits eutrophication (algae proliferation).

- To absorb benzene, volatile organic compounds, chlorine, along with certain heavy metals.

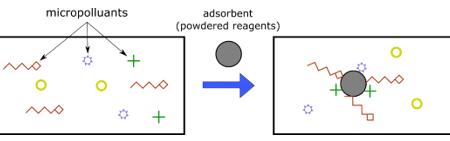

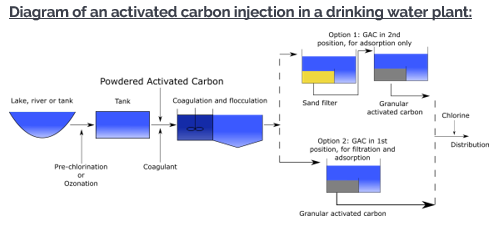

All the properties of powdered activated carbon are related to its high adsorption capacity and large contact surface. It is capable of adsorbing a multitude of elements on its surface, thus purifying the water. In water treatment, PAC is injected before coagulation to absorb pollution and improves the settling of flocs.

In a typical PAC process the chemical is mixed into a slurry before being and while being injected and conveyed into the water stream. Sodimate supplies all system components required for this process, from the PAC storage container to the mixing unit. Check out our Eductor / jet-pump turn-key solution for more details.

More information is available about the processes that use Powder Activated Carbon on the EPA website.

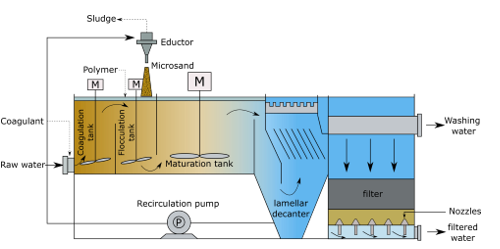

Example of microsand and polymer injection:

To enhance the floc maturation phase, microsand and polymer can be added. To inject these elements, Sodimate provides turnkey silica bulk handling systems, a mechanical bin unloader and dry polymer screw feeding systems.

The raw water passes into an injection tank where the polymers and microsand are injected. The water then remains in the maturation chamber to allow the flocs to bind to the microsand under the action of the polymer which increases the density of the floc and allows a better settling. The sand is then recirculated in the eductor in order to separate the sand from the flocs and to reuse it.