Sodimate designed an optimal turnkey pump skid system that includes pumps, valves, pressure reducers assembled on a frame made of HDPE or steel.

Pump Skid Description:

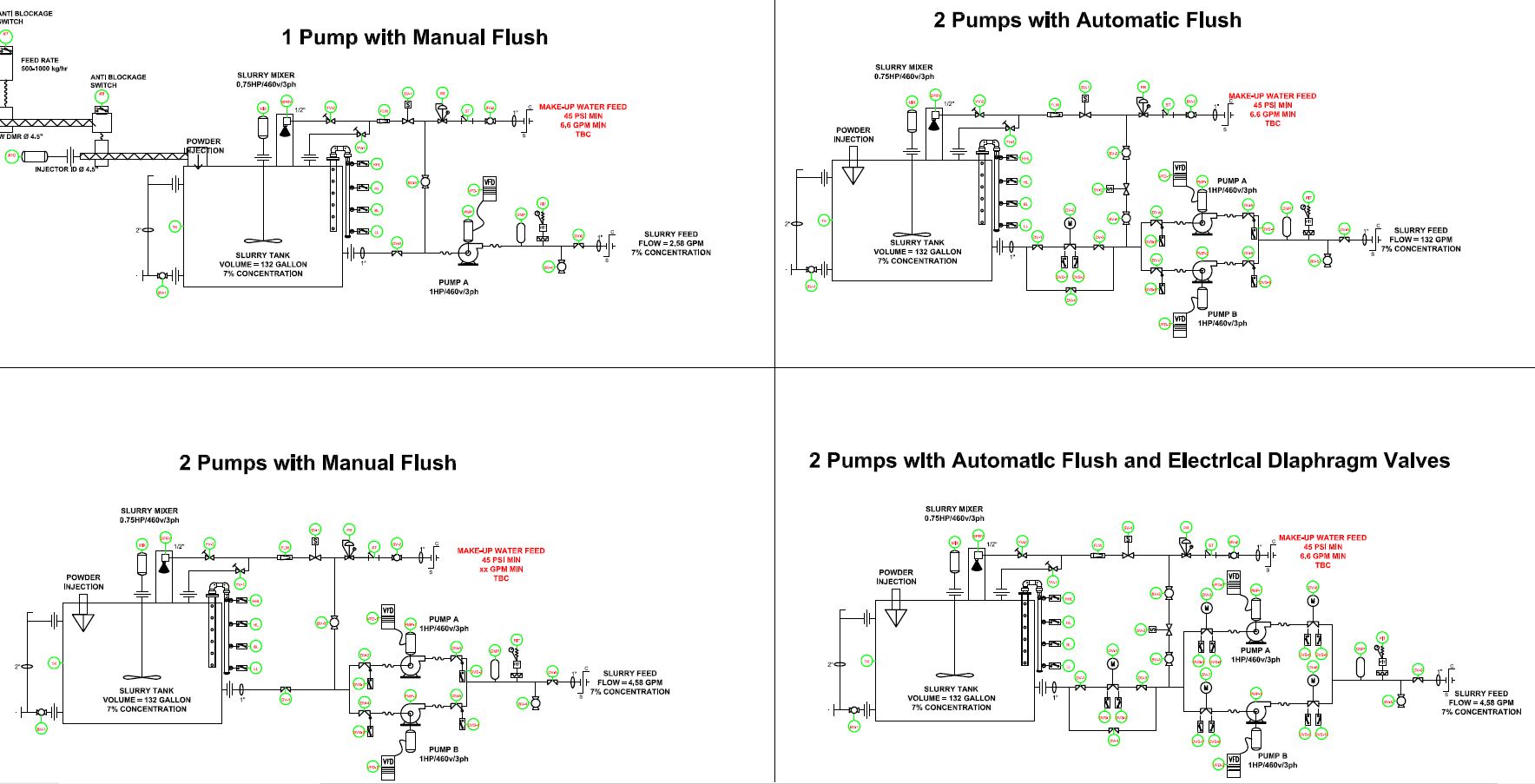

Sodimate’s skid-mounted and pre-piped slurry metering system comes equipped with pumps and all metering accessories needed for easy installation and reliable operation.

The system is most commonly used for hydrated lime , soda ash and activated carbon slurries with concentrations ranging from 2% to 30%. Additionally, the system is configured to work with Sodimate’s slurry tank and can be equipped with a control system to offer a complete slurry package.

The skids can be fabricated in corrosion resistant High-Density PolyEthylene (HDPE), carbon steel, and stainless steel. Standard skids come equipped with peristaltic pumps, a mounting panel (with solenoid valves, flowmeters, isolation valves and rinse valves) and all connections needed for slurry metering and transfer.

The skids can also include several pumps for redundancy or for multiple injection metering processes.

Pump Skid Operation:

The pump draws the liquid into a pipe due to two rotating and compressing rollers than pinch the reinforced rubber tube.

This strong compression creates a cacuum effect at the pump inlet and pushes the slurry through the oultet.

This process ensures that the slurry will only come in contact with the hose reducing the risk for contamination.

Sodimate piump skid include a flush system to easily clean the pump when stopped.

Sodimate can also integrate a backup pump with automatic switch for the pump on duty.

Centrifugal pumps are integrated per request.