Sodimate recently installed a turnkey dry sorbent injection system for an internationally recognized cement corporation to store, discharge, and convey hydrated lime into a cement kiln baghouse.

A typical lime injection system designed by Sodimate includes :

- 3000ft³ fully equipped silo fitted with filters, sensors and pressure relief valves, and load cells (used for monitoring and accurate feeding)

- Sodimate’s mechanical discharger/arch-breaker Model DDS400

- Dual shaftless screw feeder

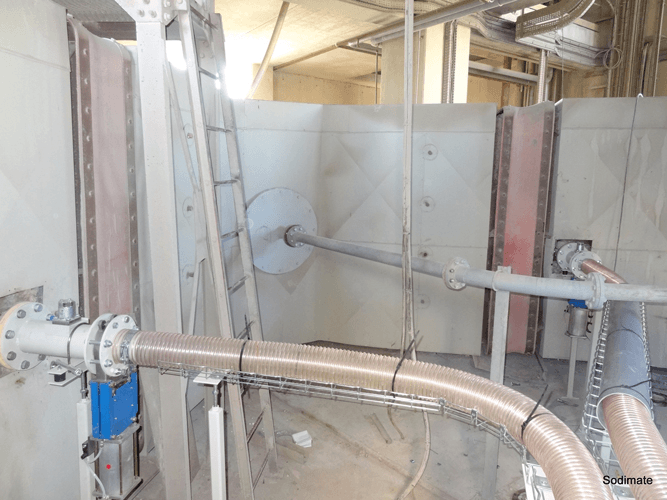

- Two independent pneumatic lime transfer systems (also known as regenerative blowers)

- A flexible pneumatic lime transfer flexible line

Sodimate’s dry sorbent injection technology has proven to reliably and effectively mitigate HG, HCL, HF SO2, & SO3 emissions.

Other benefits of Sodimate’s dry sorbent injection technology include :

- Simple and flexible designs

- Redundancy

- Easy installation

- Controlled gravimetric feed

- Adaptable for new or retrofit systems