Watch our new video to get a complete overview of our Pneumatic Transfer System:

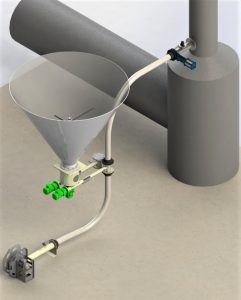

For applications where dry reagents are injected into smoke ducts, Sodimate designs and provides pneumatic transfer systems. These solutions are the best alternative to screw conveyors when the installation requires complex paths and a high injection point that would otherwise be difficult to reach.

Pneumatic transfer can convey powders over long distances, with a flow rate range from 0.5 lb/h to 2,200 lb/h.

The Sodimate Mechanical Arch Breaker discharges and doses the product stored in the silo or big-bag to a Tee to which the blower is connected. The blower then conveys the powder to the injection point through a pipe.

The transfer is done in a dilute phase, allowing us to operate with a low pressure and a cost-effective blowing device.

Advantages

- Wide selection of hoses for any application

- Operate with low pressure

- Low maintenance

- Possible to transfer over long distances

- Low investment

- Easy installation and start-up

Product conveyed

- Powered Activated Carbon

- Hydrated Lime with high specific surface area

- Soda ash

- Clay

- Dry polymer

- Etc…