Control panel: Choosing between Relay Logic control and PLC

PLCs or Relay Logic are often in our control panels, but which automation solution is a better fit for your installation?

Today’s relay-based control systems, that were originally derived ladder logic programming, are being replaced with PLCs (Programmable Logic Controller) that use this language. However, for the automation of small and simple Sodimate dry chemical feed systems, relay logic controls are still the best solution.

Larger projects including multiple units with variable speeds, the PLCs have more flexibility that can justify the higher investment.

Definitions

A relay is an electrically operated switch made of analog components to open and close circuits.

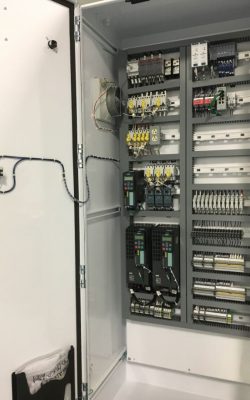

A PLC has an industrial micro-controller that executes a logic and controls a process. It has an internal logic and several IOs (input/outputs), both digital and analog. On demand, Sodimate supplies control panels and multiple brands of PLCs like Allen-Bradley, Siemens, Wago, ABB, and many others, that fit into NEMA12 type to NEMA4X enclosures.

Which is a better fit for your installation?

Cost effectiveness and space:

The process of a Relay Logic control system is simply wired in the control panel without any additional programming. These are better suited for smaller installations, with up to four motors and few sensors to detect levels or blockages. The main advantages of a relay system are the low cost and easy operation. It is the most cost-effective solution to connect a volumetric screw feeder and a single VFD to adjust the flowrate.

Larger installations that require a more complex wiring process would make using a Relay Logic control very labor intensive to design, install in the control panel and troubleshoot. In these cases, switching to a PLC makes the most sense.

Size is also a point of contention when debating between these two solutions. Adding multiple relays and wires increases the footprint of the installation, which is often a concern for production (or operators on site). If space is your main concern, a control panel with a single PLC is often a better option than a dozen of relays.

Features, performance and ease of use:

When it comes to change a functionality or to detect an issue, a relay logic-controlled installation can be easily modified or troubleshot by following the wires. For PLCs, everything is reprogrammed remotely using a software, requiring minimal interference from an on-site operator.

In terms of response time, relays react in less than 10 seconds, whereas a PLC is typically between 5 to 50 seconds slower. Despite timing issues, PLC’s can add HMI integration, soft signal transfer, better diagnostics and operation history. Sodimate’s loss in weight dosing solutions are designed with PLCs that execute instant rate control from a consign to calculate the flowrate, then display the results and various options on the HMI (Human Monitoring Interface).

Thanks to the remote access solutions this task can be executed from a distance by a programmer. On the higher end Sodimate provides PLC’s with SCADA systems and integration of communication protocols such as Ethernet/IP or Profibus.

Contact our engineers to design the automation equipment that is optimal for your dry chemical handling projet and to receive a quote.

Guillaume Souchet,

Anesha Buschanan