Sodimate installs specifically designed equipment to meet the specifications of each plant.

Water quality refining is the most essential step in water treatment processes. When done properly, it guarantees palatable taste characteristics suitable for drinking water. The reliability and accuracy of the processes for storing, metering, and dissolving the required re-agents are indispensible for successfully completing this final treatment. Outlined below is a case story about Viry-Châtillon, a water treatment plant, where Sodimate installed a new powder activated carbon (PAC) dosing unit for Eau et Force, a subsidiary of Suez – Lyonnaise des Eaux.

Thanks to a 4500 km interconnected piping network, three towns in the South of Paris region, Morsang-sur-Seine, Vigneux-sur-Seine, and Viry-Châtillon, provide and supply up to 440 000 m3 of drinking water per day to approximately one million inhabitants.

Built in 1931 and gradually expanded over several years, the plant in Viry-Châtillon can produces 120,000 m3 of drinking water each day from raw water taken from the River Seine and, to a lesser extent, underground water drawn from aquifers of the Albien and Sparnacien rivers. To produce a perfect water quality, the plant uses the most modern process. After finescreening, the water goes through ozone pre-oxidation before entering the settlement tanks. The water is then filtered through granular activated carbon to absorb the organic residue. An ozone treatment precedes a second filtration with PAC to process and neutralize micro-pollutants, thus improving the water quality. Finally, before proceeding to the final chlorination, the water’s calcium carbon ratio is adjusted to an adequate ratio.

Jean-Louis Le Hir is the Assistant Plant Manager at Viry-Châtillon, a privately owned facility. On the discussion of the management of the water treatment plant, he comments: “Lyonnaise des Eaux is the owner, via their subsidiary Eau et Force, of all of the facilities at the three main South Ile-de-France plants; which is unusual in France. Eau du sud Parisien, another subsidiary, operates the works”. Eau du Sud Parisien is in charge of servicing and maintaining all equipment and treatment processes. Additionally, they ensure that the workers implement processes and organize the water treatment plant to ensure the proper sanitation of the water produced. However important sanitation monitoring may be, ensuring taste consistency receives the most attention, as Jean-Louis Le Hir points out, “It is essential that the consumer should have water with the proper amount of nutrients and taste quality”. For this reason,the water treatment divisionof the plant in Viry- Châtillonincludes a refining step ongranular activated carbon locatedbetween the ozone preoxidationand the final disinfection.Injecting powdered PAC inthe settling tanks improves water quality by eliminating the odorcausing compounds, pesticides and their by-products, algal toxins, chlorinated hydrocarbons, and trihalomethanes and other byproducts from the disinfection process. At Viry- Châtillon, the powdered activated carbon process is used periodically, “Between”.

Since the middle of the 1960s, the plant in Viry-Châtillon used an activated carbon feeding system to deal with occasional deterioration of the raw water quality; however, the unit as outdated and no longer met current regulations. To upgrade this equipment, Eau du Sud Parisien contacted Sodimate to design and install a new activated carbon preparation and distribution unit. The objective was clear: design and install a new system taking into account the technical, safety, and environmental dimensions of the project. To do this, Sodimate chose to use the proper equipment to design a customised installation to meet the needs of their seasons, the spring or autumn rains cause deterioration of the raw water quality. The addition of activated carbon and its porous structure allows the absorption of a wide range of compounds”, specified Jean-Lois LeHir.

Integrating Sodimate’s standard equipment to design a customised installation

Founded in 1980, Sodimatespecialises in the design and installation of equipment for storing, dosing, dissolving, and mixing powdered re-agents. Over the last thirty years, whether it is drinking water, processed water or waste water, the company has acquired genuine expertise in handling dry reagents specifically for water and sludge treatment such as: hydrated lime, activated carbon, quicklime, microsand, etc. Their services range from providing reliable and efficient equipment, integrating designs, automation,

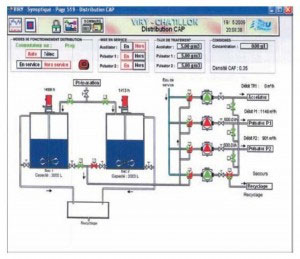

In order to use different types of activated carbon, slurry tank process was designed using load cells to, among other things, control accurately the percentage concentration of the solution. All the Each piece of equipment is automatically controlled and monitored.

Selecting and installing the equipment

The two concrete silos overlooking the station were upgraded by installing anti-explosion valves. The lower room had to meet ATEX regulations. “This lone room,” explained Zuddas, “had to match different requirements: the existing equipment, ATEX regulations, and food sanitation norms, and size constraints”. To allow the plant to function 24 hours a day, 365 days a year, the two silos alternate in discharging carbon; the first silo discharge the carbon until it reach the intermediate level and switch to the other one. To remedy the problem created by their flat bottoms, two discharge systems are installed in each silo and split into two different feeders. “Thus,” continued Zuddas, if a breakdown occurs on a line, the process is capable of automatically switching to the second”. At this level, each piece of equipment, each motor, and each seal is strictly compliant with ATEX requirements, as well as the food quality requirements.

“We follow a standard that is very close to the food industries,” Zuddas emphasized, “each piece of equipment installed must have a certificate and be validated by the owner. For example, each valve casing is both ACS certified and compliant with ATEX requirements”. To remove the constraints commonly associated with the use of different quality PAC, a new, innovative preparation device was installed with weighing cells to, among other things, control exactly the concentration of the solution. “The advantage,” explained Zuddas, “is two-fold: it avoids the problems linked to use of different quality carbons and lets an aqueous solution leave the ATEX area at the lower room”. The normal preparation cycle, that lasts 15 minutes (if necessary, an emergency procedure reduces this to less than 3 minutes), has several distinct phases to refine the dosing. Depending on the concentration needed by the operator, the quantity of carbon required is automatically set “to the gram”. The amount of carbon calculated is then introduced in a small amount of water before being dissolved in a previously weighed volume of water, in general 300 litres, to produce the slurry. This preparation is then automatically distributed in two tanks that are used alternately. “The main difficulty consisted in finding a weight indicator capable of weighing the carbon to the gram, then defining the times and speeds adapted so the powder would soak properly” stated François Jacob, Sales Director with Sodimate. Regardless of the carbon used, this technique of preparing the activated carbon ensured accuracy, safety, and autonomy without having to comply with ATEX requirements on the lower retention tanks.