Water can be classified as either hard or soft. In industrial use, it’s important to know the type of water that you are using so that you have a good idea of the processes to use for the best outcome. Read on to see the distinction between hard water and soft water, and why it matters which one you have access to get the water that you need.

What is Soft Water?

Soft water has a low mineral content, especially calcium and magnesium. This makes it less likely to cause limescale buildup and soap scum. Soft water is free of calcium and magnesium and is generally the type of water that is preferred for use in different industries and even residential settings. Rainwater, which has not had a chance to interact with substrates and therefore has no minerals in it, is generally soft water. It’s possible to collect rainwater for use in applications that require soft water.

Here are some of the benefits of using soft water:

- Reduced maintenance costs: Soft water can help reduce maintenance costs by preventing the buildup of limescale and other minerals on pipes and equipment. This can lead to longer lifespans for equipment and reduced downtime for repairs.

- Improved efficiency: Soft water can help to improve the efficiency of industrial processes by reducing friction and corrosion. This can lead to lower energy costs and increased productivity.

- Better quality products: Soft water can help to improve the quality of industrial products by reducing the presence of impurities. This can lead to increased customer satisfaction and sales.

- Improved safety: Soft water can help to improve safety in industrial settings by reducing the risk of slips and falls caused by soap scum and other build-up. This can lead to a safer work environment for employees.

What is Hard Water?

Hard water contains elevated levels of dissolved minerals, predominantly calcium and magnesium. The term ‘water hardness’ is used to describe the concentration of these minerals. Hard water can also affect the efficiency and lifespan of machines, plumbing systems, and even impact the taste of water.

As groundwater moves through rocks and the earth in general, it accumulates minerals such as calcium and magnesium, which dissolve readily in water. Hard water can be further classified into permanent and temporary. Permanent hard water needs additives to soften it and cannot be softened by boiling alone, while temporary hard water can be.

Hard water can cause a number of problems, including:

- Scale buildup on pipes and appliances

- Soap scum buildup

- Dry skin and hair

- Cloudy water

- Reduced efficiency of water-using appliances

Difference between Hard Water and Soft Water?

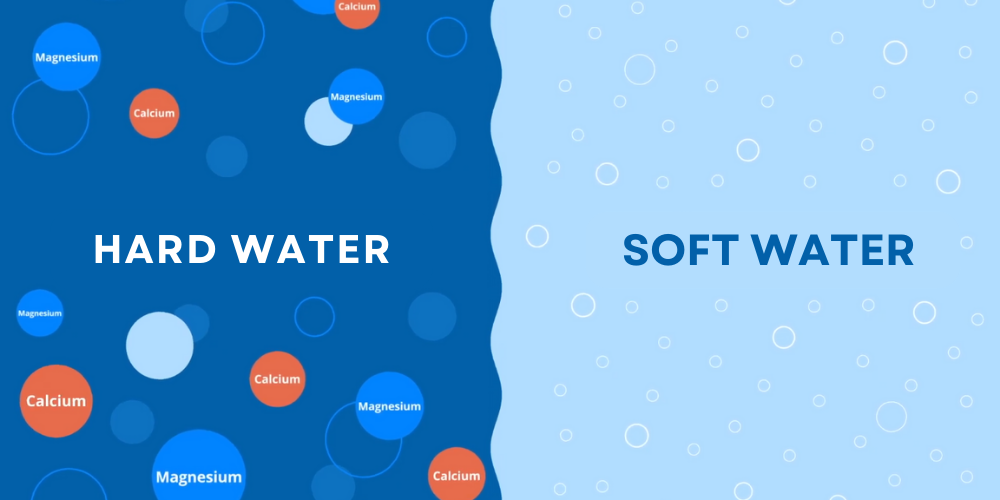

Hard water and soft water are distinguished by their mineral content. Hard water contains high levels of minerals, such as calcium and magnesium, while soft water has a low mineral content. Here are four major differences between hard water and soft water.

Hard Water Contains Minerals While Soft Water Does Not

Hard water contains magnesium and calcium, both minerals which are absent in soft water. These can change the taste of the water and make it unpleasant for some people to drink. Soft water only contains sodium ions and therefore has a more palatable taste for most people.

Hard Water Does Not Lather Easily While Soft Water Does

When soap is added to hard water, it does not lather as easily as soft water does. It takes a lot of soap to form a significant lather and also leaves soap scum on the containers in which it has been used. Soft water only needs a small amount of soap to lather and leaves no scum after it has been used.

Hard Water Can Wear Machinery and Equipment Faster Than Soft Water

When using machinery and equipment, hard water may cause more wear on the components that come into contact with it. This is because of the minerals present in it that may act as abrasives and add to the friction that the parts undergo. Soft water does not present this complication.

Hard Water Causes Stains While Soft Water Doesn’t

Using hard water leaves stains and discoloration in the places it comes into contact. This is especially noticeable on glass and steel, which will have markings on them after continued exposure to the minerals in hard water. Soft water does not leave any marks and is easy to clean up after.

How Does Hard Water Impact Industrial Uses?

Hard water has various effects in different industries. These fluctuate in severity, but it is usually recommended that the water be softened before use whenever it is practical.

Substances do not dissolve in hard water as readily as they do in soft water. This, therefore, has an impact on the quantity and quality of solutions made using hard water. Raw materials also interact differently with hard water, sometimes having unprecedented results that may call for additional processes to remedy and streamline.

Hard water affects the machinery and equipment used in different industries. It can lead to blockages throughout the plumbing and affect the temperatures and speeds of the flow of different materials in the industry. This can have disastrous effects or call for expensive solutions to reverse it.

How is Water Softened?

It’s important to soften water for industrial use. One of the two main methods that can be used to soften hard water is by adding chemicals to the hard water. These chemicals combine with the minerals in the hard water to form insoluble precipitates. These are then removed by precipitation or filtration and discarded.

The second method of softening water is by using the ion exchange method, by far the most common in industrial water softening. In this method, the water is passed through columns of resin, which exchanges the calcium and magnesium ions with sodium ions. This resin can either be natural or artificial and needs to be regenerated when the water leaving the columns is found to have traces of calcium in it.

Sodimate offers various solutions for softening water and can help you get the right equipment for your specific industry. With this, you can get soft water easily and cost-effectively, prolonging the life of your industrial equipment and improving the quality of your output. Give us a call today to find the right solution for your hard water.