Wastewater treatment is the process of converting wastewater or used water into water that can be discharged back into the environment safely. Industrial wastewater treatment covers the mechanisms and processes used to treat contaminated water.

What results into wastewater?

The main concern is the increase in synthetic compounds in wastewater as result of commercial activities or anthropogenic industries before its release into the environment or its re-use.

Though some industries are trying to recycle the waste within the production process, many industries still produce untreated wastewaters. The pollutants in industrial discharges need to be treated before being discharged into a biological treatment plant and subsequent water bodies.

Wastewater Treatment Process

The process of treating wastewater once it gets to a wastewater treatment plant involves several steps, the very first of which is bar screening. At this point, any large items in the influent are removed to avoid damaging pumps, valves, and other equipment in the facility.

In the same way, the sand that was too small to be caught in the first step is removed by grit chambers. There are different types of grit chambers in which grit is removed, and they include vortex, horizontal, and aerated grit chambers.

After this first step, a degreasing tank is used to remove the grease that floats on top of the water. This constitutes an important part of carbonaceous pollution and can easily damage the filtration work.

The water then flows into the primary clarifier, which traps particulate pollution and produces primary sludge. The clarified water is then collected on the surface by chutes and directed to the biological treatment.

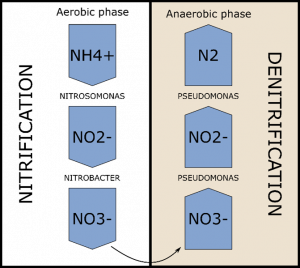

To eliminate the dissolved pollution that could not be removed by the previous steps (nitrogenous elements, phosphate, active compounds, and fine particles) the biological treatment is used. This process takes place in the aeration tank, and it consists in placing the water in aerobic conditions (presence of oxygen) and then in anaerobic conditions in order to allow certain types of bacteria to transform the nitrogen compounds into nitrogen. See the following sketch:

The gas produced by this reaction set is now safe and can be released into the environment.

Secondly, the wastewater then enters the secondary clarifier, where fine organic sediments can settle to the bottom. This sediment consists mainly of sludge and active bacteria, some of which is returned to the aeration tank while the rest is discharged.

The next stage is disinfection, which, depending on the plant, can be done by adding chlorine to the water or using UV or ozone disinfection.

The water is then tested and analyzed to make sure that residual chlorine, dissolved oxygen, nitrates, ammonia, phosphates, and the pH level all conform to the plant’s permit specifications.

Finally, the resulting clean water is released back into the environment.

Three Stages of Wastewater Treatment

There are three main stages of wastewater treatment and they’re outlined below.

Pre-treatment

Pre-treatment consists in removing the coarsest solid pollutants from the raw wastewater (screening, sand and oil removal) before it reaches the treatment plant.

Primary Stage

In this stage, the largest and heaviest solids in the water are removed by allowing them to settle at the bottom of the primary treatment tank. Once these materials settle, they’re held back while the clearer wastewater is pumped to the secondary stage. Mechanical scrapers in this tank continually drive all the sludge that’s collected to a hopper which then pumps it to treatment facilities.

Secondary Stage

In this stage, any remaining biological content is substantially degraded to purify the wastewater further. This is either done through biofiltration, aeration, or in oxidation ponds, depending on the specifics that the treatment plant in question is working with, such as climate, required purity, and funds available.

Tertiary Stage

This is the third and final stage of wastewater treatment. The aim is to bring the quality of the water to industrial and domestic standards or to meet some specific requirements. Pathogens may also be removed at this stage, to ensure that the water is safe for drinking, especially in the case of water treated by municipalities.

Advantages of Wastewater Treatment

As wastewater treatment converts dirty and polluted water back into water that can safely be used in many ways, it’s clearly beneficial both for the environment and businesses.

Here are the detailed advantages that wastewater treatment offers:

- For the general public, wastewater treatment eliminates the risk of disease by getting rid of harmful pathogens and bacteria.

- For companies, having a wastewater treatment facility gives them the potential to generate their own power. This can be done by harvesting the methane that’s emitted by the biodegradable material. There are further benefits from this, such as saving money that would have been spent on getting electricity from local suppliers.

- For businesses, there is also the potential of a new income source as the sludge from wastewater treatment can easily and cheaply be converted to fertilizer which can also be sold to farmers.

- For the environment, it will help in reducing the greenhouse effect when the methane resulting from wastewater and biological waste is harvested for electricity. An electrification system that’s powered by methane is an effective way to reduce the amount of greenhouse gas in the atmosphere.

To enjoy these benefits and live a polluted-free life, give us a call at Sodimate, and we will be glad to guide you on the steps to take. Years of experience and a team of professionals will ensure to get exactly what kind of wastewater treatment facility will serve you for your industry, like pH control, Sludge Stabilization, Taste & Odor Control, or Water Softening.